Intelligent data model for all process phases

All of the smartCable tools apply an interdisciplinary data model that not only describes mutual dependencies between participants but also models them.

The intelligence embedded in the programs facilitates consistent validation for each customer-specific configuration and also when changes are made. Generative design replaces error-prone manual processes.

The data model grows with the degree of development maturity. Tailored views of the data model are available for developers, manufacturing planners and cost accountants. The common data model makes communication between the relevant departments easier and prevents misunderstandings.

In-process communication by networking participants

The smartCable tools have functions that communicate with one another via the central data model for every phase of the production process. This means that design errors are detected as they occur. With the data model serving as a basis, external programs for electrical, thermal and mechanical simulation can be integrated as well.

Designing, evaluating, detailing, manufacturing, testing

Architecture

HiTool

Sketching and evaluation of architectures. Generative design means that the transition to the next phase is automated.

Design and detailing

V5H

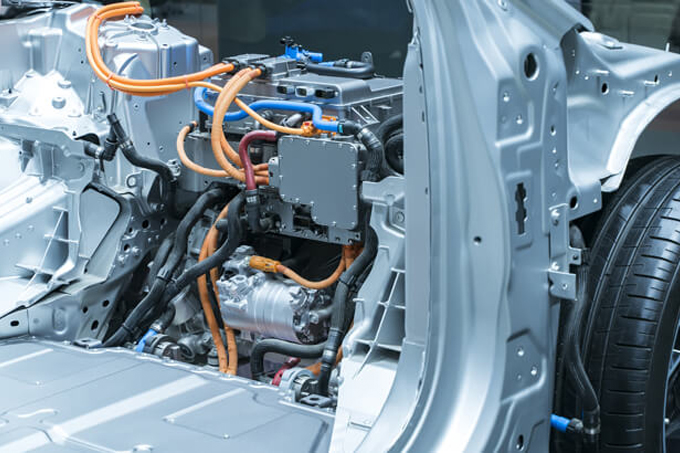

The reality is 3D, the virtual vehicle is 3D – so the electrified 3D model is the reference in all phases of the draft. All 2D views and documentation are derived from the 3D model. Every element of the drawing retains its reference to the 3D model.

Manufacturing

MS_Cable

In MS_Cable, the Manufacturing View is derived from the electrified 3D model. The manufacturing documents – formboard drawing, cutting lists, NC programs for triggering machines and the test bench – are generated.

ViVa

Managing and utilizing

engineering knowhow

Change management

CHANGE

CHANGE provides automation of the change process and synchronization of revisions based on wiring, the electrified 3D model and documentation.

Calculation of manufacturing costs

CALC

Simulation of work planning on th basis of the electrified 3D master model. Material costs ad manufacturing times on the machines needed are calculated.